-

Sand Making Crusher

- PCL-Vertical Shaft Impact Crusher

- SBM Hydraulic VSI Crusher

- VSI5X Series Impact Crusher

Calcium carbonate process

Calcium carbonate processing

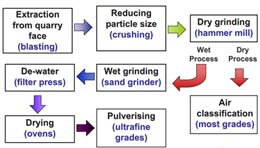

Calcium carbonates processing could be divided into those steps(left image). This website we discussing the crushing, grinding, pulverising steps,and the machines used in those steps.

Calcium carbonates crushing processing: we provide stone crushers for this step, you can choose jaw crusher,impact crusher,cone crusher,mobile crusher. The capacity of jaw crusher is 1 - 1000 t/h, and the capacity of our impact crusher is 50 - 300 t/h...for more imformation,click here start a live chat.

Calcium carbonates grinding processing: We provide Ball mill, vertical roller mill, raymond roller mill.

Wet Cement Ball Mill are used primary for single stage fine grinding.It is the key equipment that repulverzes the Calcium carbonates raw material affter it is crushed,which is widely used in the manufacture industries,such as calcium carbonates,silicate,new building material,refractory materail,fertilizer,mill run of ferrous metal,nonferrous metal and glassceramics and can be used for the dry and wet pulverzation for all kinds of ores and other grindiable materials.

Calcium carbonates pulverising processing: We provide SCM ultrafine mill, T130 Ultrafine mill for this step.

SCM series ultrafine grinding mill is a fine powder and ultrafine calcium carbonates powder production machine which can meet your fine particle processing, micronizing, fine dry grinding, air classification and other comminution requirements. The SCM ultrafine mill is a dry airswept media mill used for the production of fine alcium carbonates powders typically below 45 microns. The grinding capacity is from 350Kg/H to 7 TPH according to different models. The feed calcium carbonates raw material must be suitable for pneumatic conveying, typically all below 3 mm.

- Limestone Crusher

- Barite Crusher

- Granite Crusher

- Kaolinite Crusher

- Calcite Crushing

- Tombarthite Crusher Mill

- Bentonite Grinding Plant

- Basalt Ore Crusher

- Lignite Crusher Mill

- Silica Ore Crusher

- Tin Ore Mine

- Lead and Zinc Ore Crusher

- Ochre Crusher Mill

- Garnet Crusher

- Mica Crusher

- Asbestos Crusher

- Manganese Ore Crusher

- Talc Crusher Mill

- Feldspar Crusher

- Iron Ores Crusher

- Dolomite Crusher

- Quartz Crusher

- Gypsum Crusher

- Calcium Carbonate Grinding

- Calcium carbonate mining

- Calcium carbonate pulverizer

- Calcium carbonate beneficiation

- Calcium carbonate process

- Calcium carbonate crushing

- Calcium carbonate quarry

- About Us

- |

- Service

- |

- News & Events

- |

- Contact Us

- |

- Resources

- |

- Showroom

Aggregate Crusher

Artificial Sand Making

Ballast Crushing Machine

Basalt Stone Crusher

Barite Mine Process

Beneficiation Plant

Bentonite Crusher

Bentonite Milling

Calcium Carbonate Crusher

Calcium Carbonate Grinding

Cement Grinding

Concrete Crusher

Coal Crusher

Copper Crusher

Cement Mill

Chrome Mining Process

Copper ore Beneficiation

Coal Processing

Coal Pulvarizer

Feldspar Crushing

Feldspar Grinding

Flotation Machine

Gold Crusher

Gold Mine Equipment

Gold Processing Machinery

Granite Crusher

Granite Crushing Machine

Granite Quarry Equipment

Gypsum Crusher

Gypsum Mining

Gypsum Powder Production

Iron Ore Beneficiation

Iron Ore Crusher

Kaolin Processing Plant

Limestone Crusher

Silica Sand Crusher

Iron Ore Mining Equipment

Cement Production Line

Talc Production Line

Quartz Crushing Machine

Limestone Mining Process

Manganese Benificietion