PRODUCTS

-

Sand Making Crusher

- PCL-Vertical Shaft Impact Crusher

- SBM Hydraulic VSI Crusher

- VSI5X Series Impact Crusher

Cement manufacturing process

Home > Application > Cement manufacturing process

Cement manufacturing process

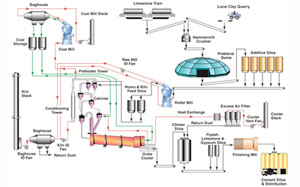

In Cement process,most of the raw materials used are extracted from the earth through mining and quarrying and can be divided into the following groups: lime (calcareous), silica (siliceous), alumina (argilla- ceous), and iron (ferriferous). We provide crushing screening, grinding machines,such as jaw crusher,cone crusher,ball mill,vertical roller mill.

- 1. The cement manufacturing process begins when limestone, the basic raw material used to make cement, is transported by rail to the Edmonton plant from the Cadomin limestone quarry 220 kilometres west of Edmonton.

- 2. The limestone is combined with clay, ground in a crusher and fed into the additive silos. Sand, iron and bottom ash are then combined with the limestone and clay in a carefully controlled mixture which is ground into a fine powder in a 2000 hp roller mill.

- 3. Next, the fine powder is heated as it passes through the Pre-Heater Tower into a large kiln, which is over half the length of a football field and 4.2 metres in diameter. In the kiln, the powder is heated to 1500 degrees Celsius. This creates a new product, called clinker, which resembles pellets about the size of marbles.

- 4. The clinker is combined with small amounts of gypsum and limestone and finely ground in a finishing mill. The mill is a large revolving cylinder containing 250 tonnes of steel balls that is driven by a 4000 hp motor. The finished cement is ground so fine that it can pass through a sieve that will hold water.

- 5. The cement manufacturing process consists of many simultaneous and continuous operations using some of the largest moving machinery in manufacturing. Over 5000 sensors and 50 computers allow the entire operation to be controlled by a single operator from a central control room.

Application

- Limestone Crusher

- Barite Crusher

- Granite Crusher

- Kaolinite Crusher

- Calcite Crushing

- Tombarthite Crusher Mill

- Bentonite Grinding Plant

- Basalt Ore Crusher

- Lignite Crusher Mill

- Silica Ore Crusher

- Tin Ore Mine

- Lead and Zinc Ore Crusher

- Ochre Crusher Mill

- Garnet Crusher

- Mica Crusher

- Asbestos Crusher

- Manganese Ore Crusher

- Talc Crusher Mill

- Feldspar Crusher

- Iron Ores Crusher

- Dolomite Crusher

- Quartz Crusher

- Gypsum Crusher

- Calcium Carbonate Grinding

Find More

- Cement hammer mill

- Cement grinding mill plant

- Cement crushing plant

- Cement process machine

- Cement pulverizer

- Vertical cement mill

- Cement ball mill

- About Us

- |

- Service

- |

- News & Events

- |

- Contact Us

- |

- Resources

- |

- Showroom

Aggregate Crusher

Artificial Sand Making

Ballast Crushing Machine

Basalt Stone Crusher

Barite Mine Process

Beneficiation Plant

Bentonite Crusher

Bentonite Milling

Calcium Carbonate Crusher

Calcium Carbonate Grinding

Cement Grinding

Concrete Crusher

Coal Crusher

Copper Crusher

Cement Mill

Chrome Mining Process

Copper ore Beneficiation

Coal Processing

Coal Pulvarizer

Feldspar Crushing

Feldspar Grinding

Flotation Machine

Gold Crusher

Gold Mine Equipment

Gold Processing Machinery

Granite Crusher

Granite Crushing Machine

Granite Quarry Equipment

Gypsum Crusher

Gypsum Mining

Gypsum Powder Production

Iron Ore Beneficiation

Iron Ore Crusher

Kaolin Processing Plant

Limestone Crusher

Silica Sand Crusher

Iron Ore Mining Equipment

Cement Production Line

Talc Production Line

Quartz Crushing Machine

Limestone Mining Process

Manganese Benificietion

Privacy Policy | © 2010 - 2011 SHANGHAI SHIBANG MACHINERY CO., LTD.