-

Sand Making Crusher

- PCL-Vertical Shaft Impact Crusher

- SBM Hydraulic VSI Crusher

- VSI5X Series Impact Crusher

Granite processing machinery

Granite processing unit

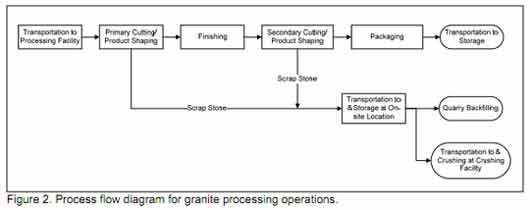

Processing operations include much more variation than extraction. Nevertheless, the general procedures begin with initial cutting, followed by application of a finish, and conclude with a second cutting or shaping step. Due to the array of stone products, the second and/or third steps may be eliminated, specifically when the product will have a “natural” appearance. Figure 2 depicts the fabrication process.

Processing commences with transportation of the (raw) stone from the quarry to the processing facility, as depicted by Figure 2. It should be noted that this step may consist of multiple transportation steps; prior to reaching the doors of the facility, the stone may be transferred to a number of vendors or distribution locations worldwide. Additionally, some granite (blocks) may have been cut into slabs before reaching the main fabrication plant. These are most commonly sliced to a thickness of 3/4 in (2 cm) or 1-1/4 in (3 cm) in lengths of approximately10-12 ft and widths around 3-5 ft. The route that the stone takes through the plant therefore depends on its physical state upon arrival, as well as the product to be produced.

Granite processing plant

We povide crushing machines, screening machines, conveyor machines and feeder machines for granite processing plant, we have capacity varying 40-1000t/h granite processing production line solutions. and our granite processing machines have been exported to more than 130 countries.Authentication by 200 thousands Customers ,Certificated by ISO9001 : 2000 Quality and Managementand EU CE . Welcome to contact us.

- Limestone Crusher

- Barite Crusher

- Granite Crusher

- Kaolinite Crusher

- Calcite Crushing

- Tombarthite Crusher Mill

- Bentonite Grinding Plant

- Basalt Ore Crusher

- Lignite Crusher Mill

- Silica Ore Crusher

- Tin Ore Mine

- Lead and Zinc Ore Crusher

- Ochre Crusher Mill

- Garnet Crusher

- Mica Crusher

- Asbestos Crusher

- Manganese Ore Crusher

- Talc Crusher Mill

- Feldspar Crusher

- Iron Ores Crusher

- Dolomite Crusher

- Quartz Crusher

- Gypsum Crusher

- Calcium Carbonate Grinding

- Granite pulverizer

- Granite processing line

- Granite screening machines

- Granite grinding machine

- Granite quarry machine

- Granite crushing machine

- About Us

- |

- Service

- |

- News & Events

- |

- Contact Us

- |

- Resources

- |

- Showroom

Aggregate Crusher

Artificial Sand Making

Ballast Crushing Machine

Basalt Stone Crusher

Barite Mine Process

Beneficiation Plant

Bentonite Crusher

Bentonite Milling

Calcium Carbonate Crusher

Calcium Carbonate Grinding

Cement Grinding

Concrete Crusher

Coal Crusher

Copper Crusher

Cement Mill

Chrome Mining Process

Copper ore Beneficiation

Coal Processing

Coal Pulvarizer

Feldspar Crushing

Feldspar Grinding

Flotation Machine

Gold Crusher

Gold Mine Equipment

Gold Processing Machinery

Granite Crusher

Granite Crushing Machine

Granite Quarry Equipment

Gypsum Crusher

Gypsum Mining

Gypsum Powder Production

Iron Ore Beneficiation

Iron Ore Crusher

Kaolin Processing Plant

Limestone Crusher

Silica Sand Crusher

Iron Ore Mining Equipment

Cement Production Line

Talc Production Line

Quartz Crushing Machine

Limestone Mining Process

Manganese Benificietion