-

Sand Making Crusher

- PCL-Vertical Shaft Impact Crusher

- SBM Hydraulic VSI Crusher

- VSI5X Series Impact Crusher

Feldspar beneficiation

Feldspar beneficiation

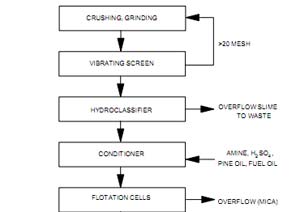

Conventional open-pit mining methods including removal of overburden, drilling and blasting, loading, and transport by trucks are used to mine ores containing feldspar. A froth flotation process is used for most feldspar ore beneficiation. The left image(click to see complete image) shows a process flow diagram of the flotation process. The ore is crushed by primary and secondary crushers and ground by jaw crushers, cone crushers, and ball mills until it is reduced to less than 841 µm (20 mesh). Then the ore passes to a three-stage, acid-circuit flotation process.

An amine collector that floats off and removes mica is used in the first flotation step. Also, sulfuric acid, pine oil, and fuel oil are added. After the feed is dewatered in a classifier or cyclone to remove reagents, sulfuric acid is added to lower the pH. Petroleum sulfonate (mahogany soap) is used to remove iron-bearing minerals. To finish the flotation process, the discharge from the second flotation step is dewatered again, and a cationic amine is used for collection as the feldspar is floated away from quartz in an environment of hydrofluoric acid (pH of 2.5 to 3.0).

If feldspathic sand is the raw material, no size reduction may be required. Also, if little or no mica is present, the first flotation step may be bypassed. Sometimes the final flotation stage is omitted, leaving a feldspar-silica mixture (often referred to as sandspar), which is usually used in glassmaking.

From the completed flotation process, the feldspar float concentrate is dewatered to 5 to 9 percent moisture. A rotary dryer is then used to reduce the moisture content to 1 percent or less. Rotary dryers are the most common dryer type used, although fluid bed dryers are also used. Typical rotary feldspar dryers are fired with No. 2 oil or natural gas, operate at about 230EC (450EF), and have a retention time of 10 to 15 minutes. Magnetic separation is used as a backup process to remove any iron minerals present. Following the drying process, dry grinding is sometimes performed to reduce the feldspar to less than 74 µm (200 mesh) for use in ceramics, paints, and tiles. Drying and grinding are often performed simultaneously by passing the dewatered cake through a rotating gas-fired cylinder lined with ceramic blocks and charged with ceramic grinding balls. Material processed in this manner must then be screened for size or air classified to ensure proper particle size.

- Limestone Crusher

- Barite Crusher

- Granite Crusher

- Kaolinite Crusher

- Calcite Crushing

- Tombarthite Crusher Mill

- Bentonite Grinding Plant

- Basalt Ore Crusher

- Lignite Crusher Mill

- Silica Ore Crusher

- Tin Ore Mine

- Lead and Zinc Ore Crusher

- Ochre Crusher Mill

- Garnet Crusher

- Mica Crusher

- Asbestos Crusher

- Manganese Ore Crusher

- Talc Crusher Mill

- Feldspar Crusher

- Iron Ores Crusher

- Dolomite Crusher

- Quartz Crusher

- Gypsum Crusher

- Calcium Carbonate Grinding

- Feldspar process equipments

- Feldspar quarry machinery

- Feldspar mining process

- Feldspar Crusher

- Feldspar grinding equipments

- Feldspar beneficiation process

- About Us

- |

- Service

- |

- News & Events

- |

- Contact Us

- |

- Resources

- |

- Showroom

Aggregate Crusher

Artificial Sand Making

Ballast Crushing Machine

Basalt Stone Crusher

Barite Mine Process

Beneficiation Plant

Bentonite Crusher

Bentonite Milling

Calcium Carbonate Crusher

Calcium Carbonate Grinding

Cement Grinding

Concrete Crusher

Coal Crusher

Copper Crusher

Cement Mill

Chrome Mining Process

Copper ore Beneficiation

Coal Processing

Coal Pulvarizer

Feldspar Crushing

Feldspar Grinding

Flotation Machine

Gold Crusher

Gold Mine Equipment

Gold Processing Machinery

Granite Crusher

Granite Crushing Machine

Granite Quarry Equipment

Gypsum Crusher

Gypsum Mining

Gypsum Powder Production

Iron Ore Beneficiation

Iron Ore Crusher

Kaolin Processing Plant

Limestone Crusher

Silica Sand Crusher

Iron Ore Mining Equipment

Cement Production Line

Talc Production Line

Quartz Crushing Machine

Limestone Mining Process

Manganese Benificietion